Engineering projects

Mail: sales@elcoint.com

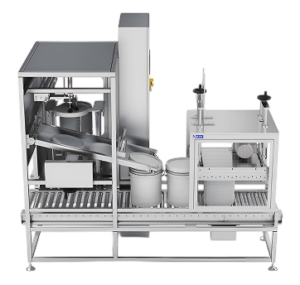

• The filling nozzle is manufactured with integrated craftsmanship to prevent dripping and splashing.

• Filling is carried out in large, medium, and small stages for higher accuracy.

• No filling is allowed without a barrel on the weighing platform, with differential pressure protection to prevent barrel collisions.

• Equipped with a fault alarm and display function for quick emergency handling.

Product model

GPMI-GAF-10S8-AH

Filling capacity

900 - 1200(barrels/h)

Filling volume

1 - 5kg

Filling accuracy

± (2 ~ 10)g

Graduation value

1 / 2 / 5 g

Power supply

AC220V 50Hz

Air supply

0.5 - 0.7 Mpa

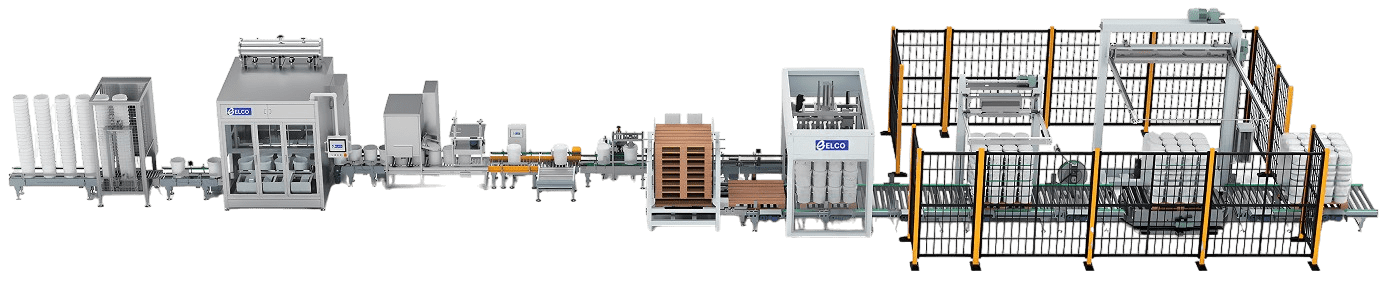

These machines are fully automated weighing and filling systems specifically designed for 10–30 kg square drums. They streamline the production process by integrating functions such as manual loading, automatic conveying, positioning, filling, capping, re-weighing, labeling, stacking, packaging, and palletizing.

The system uses a weight-based filling method, with the filling nozzle and pneumatic ball valve precisely controlled by a PLC and weighing module to ensure accurate measurement and minimize waste.

Safety features—such as differential pressure collision protection and no-fill operation when no drum is present—enhance reliability. These machines feature a user-friendly touchscreen interface and adjustable mechanisms to accommodate various drum sizes, offering high production efficiency and versatility, making them ideal for a wide range of industrial applications.

Filling capacity

160 - 500(barrels/h)

Filling volume

10 - 30kg

Filling accuracy

5 - 40 g

Power supply

50Hz

Air supply

0.5 - 0.7 Mpa

These fully automatic filling machines are specifically designed for 200L drum applications, featuring advanced weighing-based filling, robust safety mechanisms, and a streamlined process—from manual drum loading to final palletizing. A pre-alignment system ensures precise nozzle entry and centering in the drum, while differential pressure anti-collision protection prevents damage and disables filling when a drum is not detected on the scale.

Key features include an enclosed design with a gas collection hood and drip tray to minimize environmental impact, as well as dual-tube filling nozzles that support nitrogen purging before and after filling. The system is capable of handling tasks such as automatic drum feeding, positioning, capping, re-weighing and rejection, labeling, and palletizing. It integrates with drum storage systems to create a fully connected smart workflow, addressing common challenges in the chemical industry such as spills and leaks.

Additional functions like automatic cap detection and locking ensure reliable, leak-free filling and a high capping success rate. Built-in intelligent features provide error detection and real-time equipment status monitoring. Multi-nozzle configurations allow the system to handle various materials with ease. In summary, these machines offer high automation, user-friendly operation, and excellent efficiency, making them an ideal solution for a wide range of industrial applications.

Filling capacity

20 - 50(barrels/h)

Filling volume

100 - 300kg

Filling accuracy

100 - 2000 g

Power supply

50Hz

Air supply

0.5 - 0.7 Mpa

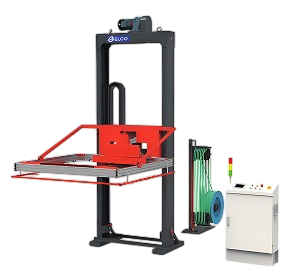

These intelligent filling systems are specifically designed to handle 200L × 4 drums (placed on pallets) and IBC totes. A vision-based mouth detection feature automatically locates and aligns the drum openings, while nitrogen purging, sub-surface filling, and nitrogen sealing help minimize foaming, static buildup, and product loss. The swing-arm design allows the filling nozzle to move in multiple directions, ensuring precise positioning and easy adaptation to various drum heights.

Key safety measures include no-drum-no-fill protection, anti-collision safeguards, and a robust dual-layer weighing platform that protects load cells from impact. Automatic lid opening, drip collection, and capping reduce manual intervention, enhancing efficiency and cleanliness. An optional dual-nozzle configuration supports the filling of two different liquids, while user-friendly controls—such as pneumatic quick-operation handles—simplify setup and operation.

In summary, these machines offer a high level of automation, durability, and versatility for large-volume liquid filling applications.

Filling capacity

20 - 50(barrels/h)

Filling volume

100 - 300kg

Filling accuracy

100 - 2000 g

Power supply

50Hz

Air supply

0.5 - 0.7 Mpa

This product category includes a complete set of auxiliary systems designed to support automated filling and packaging lines for various container types, including 10–30 kg small-neck square drums, tin flower basket drums, and plastic open-lid paint buckets. The series of equipment streamlines every stage of the process—from handling and separating stacked containers to feeding empty ones into the filling line—ensuring minimal manual intervention and maximizing production efficiency.

- Drum Handling System: These devices use a vertical separation method to automatically separate stacked drums and are equipped with lifting mechanisms to prevent damage. Empty drums are transferred from temporary storage to the conveyor according to the filling line’s needs. A built-in drum-missing alarm ensures continuous and error-free operation.

- Lid and Capping Equipment: These systems are custom-designed for different types of containers, featuring automatic lid sorting, gripping, precise placement, and sealing through pressing or rolling. They offer accurate lid positioning with adjustable settings and detection alarms to address issues such as missing or loose lids, ensuring tight sealing and leak prevention.

- Labeling and Packaging Solutions: Integrated touchscreen interfaces support bilingual operation for easy setup and real-time adjustments. Advanced labeling systems automatically correct misaligned labels, while robotic palletizers, stretch wrappers, and strapping machines secure finished products, ensuring stable transport and reduced waste.

Filling volume

50 - 2500kg

Power supply

AC380V 50Hz

Air supply

0.5 - 0.7 Mpa

This system adopts a weight-based filling method, where the pneumatic ball valve and filling nozzle are precisely controlled through a weighing module connected to a PLC. The entire production line automatically completes the processes of drum separation, drum feeding and discharging, filling, capping and pressing, re-weighing and rejection, labeling, palletizing, strapping, and top-film wrapping. Finished pallets are then transported by forklift.

• Automatic vertical drum separator • Fully automatic weighing and filling machine • Automatic lid placing and pressing machine • Inline checkweigher and rejection system • Automatic round drum rotating and labeling machine • Automatic handle alignment machine • Gantry-type palletizer • Automatic pallet dispenser • Horizontal strapping machine • Automatic top film wrapping machine

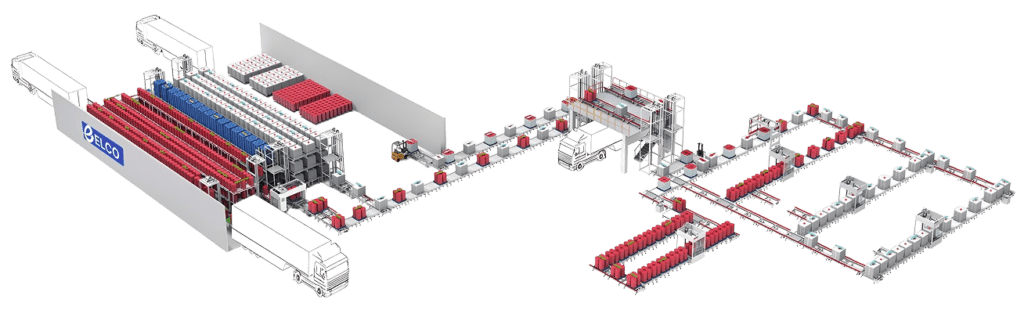

The project covers both the production filling line and the intelligent warehousing system, enabling seamless integration between the filling line and warehouse information. Controlled automatically by the central control system, the system retrieves the corresponding 200L or IBC containers from the warehouse based on current filling demand and delivers them to the appropriate automatic filling line. After filling is completed, AGV forklifts transport the filled containers.

Adding {{itemName}} to cart

Added {{itemName}} to cart