Engineering projects

Mail: sales@elcoint.com

ON-KDN High-Purity Nitrogen Air Separation Unit, ON-KDO Cryogenic Oxygen Production Air Separation Unit

This product series adopts various process configurations such as direct flow, counterflow, single-column, and double-column designs to meet customer requirements across different pressure levels. The complete system can be equipped with either DCS or PLC automation control to ensure stable and efficient operation. Additionally, by introducing low-pressure processes into cryogenic oxygen and combined oxygen-nitrogen production, energy consumption is effectively reduced while operational safety is enhanced. Professional chemical engineering software is used for process distillation calculations and equipment structure optimization, ensuring advanced technology and reliable design.

To better meet market demands, the company not only produces conventional externally compressed air separation units but has also developed a range of internally compressed process systems. These significantly reduce the workload of on-site installation and routine maintenance. Furthermore, the modular design of the purification system minimizes the complexity of on-site piping and shortens construction time, greatly improving overall installation efficiency.

Product

15~45

Oxygen Purity

≥99.6% O₂

Start-up Pressure

1.0 MPaG

Pressure

20 MPaG (adjustable)

Nitrogen Purity

≥99.999%

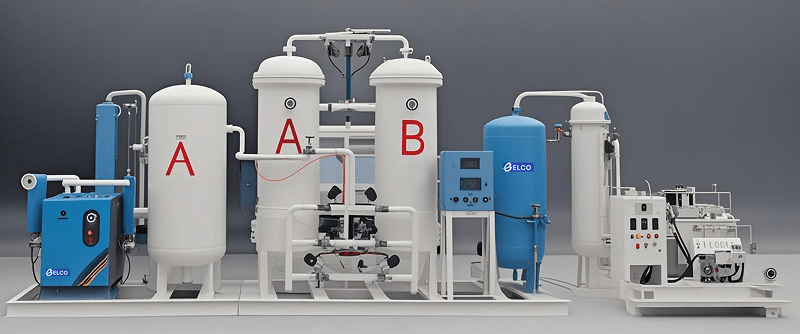

ONN-Y Small-Scale Liquid Nitrogen Unit

The ONN-Y series liquid nitrogen units operate based on the principle of pressure swing adsorption (PSA), using high-quality carbon molecular sieves as the adsorbent to extract nitrogen from air under certain pressure conditions. Compressed air, after purification and drying, undergoes pressurized adsorption and depressurized desorption in the adsorption vessels. Due to kinetic effects, oxygen diffuses much faster than nitrogen in the micropores of the carbon molecular sieve. Before equilibrium is reached, nitrogen becomes enriched in the gas phase, resulting in high-purity nitrogen as the final product. The system then depressurizes to atmospheric pressure to desorb oxygen and other impurities, regenerating the adsorbent. Typically, the system includes two adsorption towers: one for nitrogen production and the other for desorption and regeneration. The two towers alternate in operation under fully automatic PLC control. The resulting nitrogen gas is then liquefied using a Stirling cryocooler to produce liquid nitrogen.

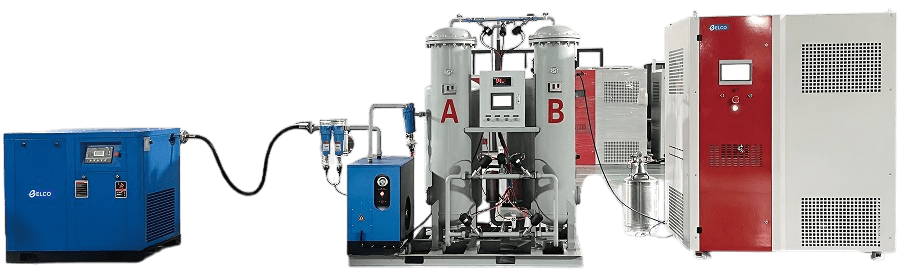

ONO PSA Oxygen Generation Unit, ONN PSA Nitrogen Generation Unit, VPSA Oxygen Generation Unit

This product series is based on the principle of Pressure Swing Adsorption (PSA), utilizing high-quality carbon molecular sieves as the adsorbent. By leveraging the difference in diffusion rates between oxygen and nitrogen molecules under pressure, efficient gas separation is achieved. Under certain pressure conditions, the carbon molecular sieve selectively adsorbs a large amount of oxygen, enriching nitrogen in the gas phase. When the system pressure is reduced, the adsorbed oxygen is rapidly desorbed, regenerating the sieve and enabling continuous cyclic operation.

The system adopts a dual-tower alternating process, where one tower performs nitrogen production through adsorption while the other undergoes desorption and regeneration. This ensures continuous and stable output of high-purity nitrogen around the clock. An advanced microcomputer controller enables equipment communication and system integration, ensuring excellent performance. High-quality butterfly valves guarantee fast switching, precise operation, and reliable performance. A gas distribution device ensures even airflow within the towers, and a unique packing method extends the lifespan of the adsorbent. During regeneration, waste heat from the air compressor is efficiently utilized to reduce energy consumption. The system features a compact layout, rational structure, easy installation, and convenient maintenance, fully meeting the industrial demand for high-purity nitrogen.

ONX Heatless Adsorption Compressed Air Dryer

ONY Heat Recovery Regenerative Compressed Air Dryer

ONL Refrigerated Compressed Air Dryer

Equipped with an industry-leading microcomputer controller, this product enables real-time communication and integrated control management, ensuring exceptional performance and high stability under various operating conditions. The core components use high-quality butterfly valves for fast, precise, and reliable switching, significantly improving system responsiveness and overall efficiency.

In addition, the uniquely designed gas distribution system ensures even airflow within the towers. Combined with an innovative packing process, it greatly extends the service life of the adsorbent while maintaining excellent adsorption performance during long-term operation. In the regeneration process, waste heat from the air compressor is effectively utilized, enabling energy-efficient and high-performance regeneration, which reduces energy consumption and lowers overall operating costs.

With a compact structure, rational layout, easy installation, and simple maintenance, this advanced industrial system integrates high performance, energy efficiency, environmental friendliness, and intelligent control. It is widely applicable to various gas drying, dehydration, and related process systems.

Air Handling Capacity

1~500 Nm³/min

Operating Pressure

0.6~1.0 MPa

Product Gas Dew Point

≤ -23°C(Atmospheric Dew Point)

Rated Inlet Air Temperature

≤ 45°C(Min 5°C)

Ambient Temperature

≤ 42°C(Min °C)

Air Inlet and Outlet Pressure Drop

≤ 0.02 MPa

This series of home oxygen concentrators (ONO-5L to ONO-60L) utilizes advanced Pressure Swing Adsorption (PSA) technology, employing high-efficiency zeolite molecular sieves to purify oxygen. The output oxygen concentration reaches 93–95%, with customizable flow rates of 5L, 10L, 15L, 20L, and 30L to meet the diverse oxygen needs of different users.

The unit features a compact design, measuring approximately 50 × 33.5 × 66 cm, with a rated power of 600W and a net weight of about 40 kg. It operates reliably on a 220V/50Hz power supply and maintains a low noise level below 70 dB(A), making it suitable for use in homes, nursing facilities, and small medical institutions with minimal environmental disturbance. The user-friendly control and display panel ensures simple, intuitive operation. Built-in features like an automatic drain and condenser facilitate daily maintenance and help extend the device’s service life. For enhanced comfort during oxygen therapy, an optional humidification module is available to increase oxygen moisture levels.

Model

ONO-5L ~ ONO-60L

Technology

Pressure Swing Adsorption (PSA)

Molecular Sieve

Zeolite Molecular Sieve

Rated Power

600W

Applicable Power Supply

~220V / 50HZ

Noise Level

≤ 70 dB(A)

Adding {{itemName}} to cart

Added {{itemName}} to cart