Engineering projects

Mail: sales@elcoint.com

The stainless steel reactor (heated by electricity, steam, or thermal oil) consists of a lid, vessel body, jacket, agitator, shaft sealing drive device, and support structure. The body and all parts in contact with the material are made of corrosion-resistant stainless steel plates such as OCr18Ni9 or 1Cr18Ni9Ti.

Nominal capacity (L)

50 - 3000

Electric heating power (kW)

30 - 150

Inner vessel diameter (mm)

400 - 1600

Jacket diameter (mm)

600 - 1800

Stirring speed (rpm)

60 - 100

Our reactors are equipped with electric heating, steam heating, or thermal oil heating systems to meet various production needs and operating conditions. Made from acid-resistant stainless steel (OCr18Ni9 or 1Cr18Ni9Ti), they ensure durability, corrosion resistance, and compliance with industry standards.

The CR-KF series enamel-lined glass reactors from Henan Shenglong are designed to deliver reliable performance under pressures ranging from 0.2 MPa to 1.0 MPa, with a maximum jacket pressure of up to 0.6 MPa. These reactors offer a variety of agitator options, vertical reducers, and customizable shaft seals (stuffing box or mechanical). Manufactured according to the HG/T2371-92 standard, they are available in reinforced configurations, making them ideal for demanding chemical processes requiring durability and precision.

Model

CE-SPA

Nominal volume (L)

50 - 6300

Actual volume (L)

70 - 6735

Heat exchange area (m²)

0.54 - 16.4

Inspection port (mm)

80 - 300x400

Reference weight (kg)

380 - 5630

A compact, high-precision reactor with a volume range of 25–1000 mL, designed for temperatures up to 300°C and pressures up to 15 MPa. It features a quick-open lid, stirring speeds of 150–1000 rpm, and temperature control accuracy of ±1°C. Customization with special materials such as Hastelloy and titanium is available, ensuring suitability for a wide range of specialized applications.

Model

CR-FDW

Volume (mL)

25 - 1000

Opening method

One-twist quick opening

Stirring speed (r/min)

150 ~ 1000

Design pressure (MPa)

15

Design

300

The CR-FDL vertical reactor is designed for versatile and precise applications in both industrial and laboratory settings. With a volume range of 1–29 liters, it supports design pressures up to 15 MPa and temperatures between 300–350°C, ensuring reliable operation under demanding conditions. It features a one-touch quick-lock mechanism or flange bolts for safe and efficient use. The reactor offers ±1°C temperature control accuracy and variable stirring speeds from 150–1000 rpm (500 rpm for models 5L and above), making it suitable for a wide range of mixing requirements.

Model

CR-FDL

Volume (mL)

1 - 29

Opening method

Flange bolts

Stirring speed (r/min)

150 ~ 1000

Design pressure (MPa)

15

爆破压力(MPa)

12.5

Application: Polymer materials and fine chemicals

Features: Distillation, component separation, vacuum control, granulation, high-temperature discharge

Opening method

法兰螺栓

Design temperature (℃)

350

Design pressure (bar)

50

Burst pressure (bar)

45

Stirring speed (r/min)

50 ~ 300

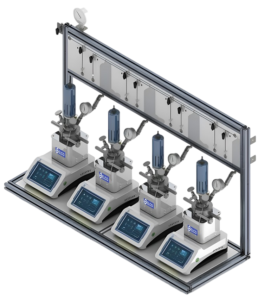

Features: Supports multi-station comparative experiments.

Gas inlet system: Customizable according to customer requirements, with flexible switching between constant temperature with different pressures and constant pressure with different temperatures.

Opening method

挡圈类型

Design temperature (℃)

350

Design pressure (MPa)

15 / 25

Burst pressure (MPa)

12.5 / 22.5

Stirring speed (r/min)

150 ~ 1000

Adding {{itemName}} to cart

Added {{itemName}} to cart